Garage Door Opener Repair

Repairs | New Doors | Openers | Parts & Accessories

Garage Door Opener Repair: Professional Troubleshooting and Maintenance Service Solutions

Automatic garage door malfunctions represent a significant inconvenience for residential and commercial property owners, often resulting from complex mechanical and electrical failures within the operating system. Professional Garage Door Opener Repair services address these challenges through systematic diagnostics and precision corrections, ensuring reliable daily operation. Understanding the components, common failures, and repair methodologies enables informed decision-making regarding maintenance investments and service selection.

Contemporary opener systems integrate sophisticated electronics, mechanical drive mechanisms, and safety protocols that require specialized knowledge for effective restoration. When door won’t close or door won’t open issues arise, the underlying causes may span multiple interconnected systems requiring comprehensive assessment. This article examines the critical aspects of opener repair, from identifying component failures to selecting qualified service providers for emergency repair situations.

Garage Door Motor Problems and Diagnostic Assessment

The garage door motor serves as the primary power source for the entire operating system, converting electrical energy into mechanical motion through complex internal components. When opener motor problems manifest, symptoms typically include humming motor sounds without door movement, dead motor conditions with no response to activation attempts, or intermittent operation suggesting electrical connection failures. A qualified garage door technician must systematically evaluate power supply issues, circuit breaker tripped conditions, and internal motor winding integrity to isolate the specific failure point.

Motor diagnostic procedures involve voltage testing at multiple connection points, capacitor functionality verification, and mechanical load assessment to distinguish between electrical failures and transmission problems. The capacitor component stores electrical charge to provide starting torque, and capacitor failure frequently presents as a motor that hums but doesn’t work when activation is attempted. Professional repair service protocols include testing under load conditions, measuring current draw patterns, and evaluating thermal cutoff switch functionality to ensure comprehensive motor system assessment before recommending repair or replacement solutions.

How to Repair Garage Door Opener Motor Components?

Motor repair procedures depend entirely on the specific component failure and the unit’s overall condition and age. For capacitor failures, replacement involves disconnecting power, safely discharging the existing capacitor, removing mounting hardware, and installing an exact replacement with proper microfarad rating and voltage specifications. Brush-type motors may require brush replacement or commutator cleaning, while permanent magnet motors typically necessitate complete unit replacement when internal components fail.

The decision between motor replacement and complete opener replacement hinges on factors including unit age, availability of replacement parts, and comparative cost analysis. Systems exceeding ten years of service often warrant complete replacement due to outdated safety features and improved efficiency in contemporary models. A contractor or handyman may attempt basic repairs, but complex motor diagnostics and logic board integration typically require specialized expertise from manufacturers like Overhead Door, Sears, or Raynor authorized service providers.

Remote Control and Wall Switch Communication Failures

Remote not working conditions represent the most frequently reported opener issues, stemming from battery depletion, programming loss, or receiver system failures within the main unit. The troubleshooting process begins with simple battery replacement in the remote control device, followed by syncing remote procedures according to manufacturer specifications. When multiple remotes simultaneously cease functioning, the issue typically resides in the opener’s receiver component or antenna connection rather than individual transmitter units.

Wall button failure presents distinct diagnostic challenges, as these hardwired control panels eliminate battery and transmission variables from the equation. A wall button not working condition suggests wiring degradation, connection point corrosion, or control panel circuit failure within the switch assembly itself. Electrician expertise may be required for tracing low-voltage wiring through walls and identifying break points in the conductor pathways between the opener and wall-mounted control stations.

What Causes Keypad Malfunction and Programming Issues?

External keypad units experience environmental exposure that accelerates component degradation compared to protected indoor devices. Moisture infiltration compromises circuit integrity, temperature extremes affect button responsiveness, and accumulated debris interferes with proper key contact. Keypad installation quality significantly influences longevity, with improper sealing allowing water ingress that corrodes internal electronics and renders the unit inoperative.

Programming remote and reset opener procedures follow manufacturer-specific protocols that vary considerably across brands such as Skylink and other major manufacturers. Most systems require accessing a learn button on the main unit, initiating programming mode, then transmitting a signal from the remote control or keypad within a specified time window. When standard programming procedures fail, receiver replacement may be necessary, particularly in older systems lacking Wi-Fi connectivity and smart home integration capabilities found in contemporary models.

Safety Sensors and Photo Eye Alignment Problems

Photo eye sensors constitute critical safety components that prevent door closure when obstructions occupy the opening pathway, protecting persons and property from crushing injuries. Sensor alignment issues represent the predominant cause of door won’t close problems, as even minor misalignment breaks the infrared beam connection between transmitting and receiving units. The photo eye blocked condition triggers immediate reversal or prevents closing initiation, with indicator lights typically signaling the malfunction through specific flash patterns.

Professional sensor repair involves precise alignment verification, mounting bracket adjustment, and lens cleaning to ensure unobstructed beam transmission. Sensor wiring problems occasionally develop where conductors connect to the main opener unit or at the sensor mounting points themselves. A locksmith or specialized garage door service provider possesses the diagnostic tools and calibration equipment necessary for verifying proper sensor function, including beam strength measurement and response time verification during obstruction tests.

Why Does Auto-Reverse Not Working Create Safety Hazards?

The auto-reverse mechanism serves as the primary safety feature preventing injury and property damage during closing operations. When this safety reversal system fails, the door continues downward despite encountering resistance, creating dangerous conditions for children, pets, and vehicles. Door reversing immediately upon closing initiation typically indicates overly sensitive force adjustment settings, while failure to reverse upon obstruction suggests force setting problems or mechanical binding requiring immediate attention.

Safety check procedures mandated by industry standards include monthly obstruction tests and reversal test verification. Placing a solid object such as a wooden board in the door’s path should trigger immediate reversal within two inches of contact. Annual maintenance protocols performed by authorized service providers include comprehensive safety sensor test procedures, force adjustment calibration, and sensitivity adjustment optimization to maintain compliance with current safety standards while ensuring reliable operation.

Chain Drive and Belt Drive Transmission Failures

The drive mechanism connecting the motor to the trolley carriage determines operational characteristics including noise levels, maintenance requirements, and common failure modes. Chain drive systems offer durability and cost-effectiveness but generate more noise and require periodic lubrication and tension adjustment. Belt drive mechanisms provide quieter operation with reduced maintenance needs but may experience belt slipping conditions when tension decreases or pulley alignment degrades over time.

Screw drive issues present distinct characteristics, with these systems utilizing a rotating threaded rod to propel the carriage assembly. When opener running but door not moving conditions occur, the problem often involves trolley carriage broken components, chain off track situations, or disconnected trolley conditions where the emergency release mechanism has been activated. A garage door technician assesses drive belt integrity, chain loose conditions, and rail assembly alignment to determine whether component replacement or adjustment provides the appropriate solution.

How to Fix Garage Door Opener Chain and Sprocket Problems?

Chain off sprocket repair requires complete tension release, sprocket realignment, and proper chain routing around the gear sprocket and idler assemblies. The gear and sprocket replacement process becomes necessary when teeth show significant wear or when stripped gear conditions prevent proper engagement with the chain links. Grinding noise emanating from the opener typically indicates gear deterioration, with metal particles often visible in the housing as evidence of advanced wear.

The worm gear assembly within the motor housing transfers rotational motion from the motor shaft to the main drive sprocket. Broken gear conditions in this critical component produce clicking sound patterns as the motor operates without engaging the drive mechanism. Professional gear replacement requires complete disassembly of the motor housing, extraction of the damaged component, and installation of manufacturer-specified replacement parts with proper lubrication application to ensure longevity and quiet operation.

Circuit Board and Logic Board Electronic Failures

The logic board serves as the control center for all opener functions, processing inputs from wall switches, remote receivers, and safety sensors while managing motor operation and travel settings. Circuit board repair becomes necessary when electrical surges, component aging, or manufacturing defects compromise board functionality. Symptoms of logic board replacement needs include erratic operation patterns, failure to respond to multiple input sources simultaneously, and inability to maintain programmed settings.

Power issues affecting the main circuit board may originate from external sources including inadequate electrical supply, voltage fluctuations, or damaged power supply components on the board itself. The RPM sensor provides feedback to the logic board regarding motor speed and door position, enabling precise travel limit control and obstacle detection. When this sensor fails, the system cannot accurately determine door position, resulting in travel limit problems where the door fails to open or close completely.

What Does Capacitor Failure Mean for Opener Function?

The capacitor provides the electrical phase shift necessary for single-phase motors to develop starting torque, functioning as an essential component in most residential garage door opener designs. Capacitor replacement cost remains relatively modest compared to motor replacement, making this diagnosis favorable when starting problems occur. A failed capacitor presents with characteristic symptoms including motor humming without rotation, intermittent starting requiring manual door assistance, or complete failure to initiate operation despite receiving activation signals.

Testing capacitor functionality requires specialized equipment including capacitance meters and discharge tools for safe handling of stored electrical energy. Visual inspection may reveal bulging cases, leaking electrolyte, or burnt connection terminals indicating definitive failure. Replacement procedures necessitate exact specification matching including microfarad rating, voltage rating, and terminal configuration to ensure compatibility with the specific motor design and electrical characteristics.

Limit Switch and Force Adjustment Calibration

Travel limit adjustment controls the precise stopping points at both fully open and fully closed positions, preventing motor strain and ensuring complete door sealing. Up limit and down limit settings utilize mechanical switches or electronic sensors to detect carriage position and signal the logic board to terminate motor operation. When garage door opener won’t close all the way or fails to open completely, limit switch adjustment represents the primary corrective action, involving incremental dial or screw adjustments until proper travel distance is achieved.

Force adjustment repair addresses the motor’s power application during opening and closing cycles, with separate settings for open force and close force parameters. Excessive force settings may prevent proper safety reversal function, while insufficient force causes incomplete travel or reversal when encountering normal resistance. Adjustment service procedures require incremental modifications followed by complete operational testing, including obstruction test verification to confirm that safety systems respond appropriately across the full range of operating conditions.

How Much Does Garage Door Opener Repair Cost for Professional Service?

Professional garage door opener repair costs vary significantly based on failure type, required components, and regional service rates. Basic repairs such as sensor alignment repair or remote programming service typically range from seventy-five to one hundred fifty dollars, while complex issues requiring motor replacement or circuit board replacement may exceed three hundred dollars including parts and labor. Same day garage door opener repair services often command premium pricing reflecting scheduling priority and expedited response.

Platforms such as HomeAdvisor and Angie’s List provide cost benchmarking data and contractor reviews facilitating informed service provider selection. The garage door opener repair vs replacement decision should consider unit age, cumulative repair history, and technological advantages of contemporary systems including Wi-Fi connectivity capabilities and enhanced safety features. Emergency garage door opener repair service commands higher rates but provides essential restoration when security or weather protection concerns require immediate attention.

Professional Repair Service Selection and Maintenance Programs

Selecting qualified service providers requires evaluating credentials, manufacturer authorizations, and customer feedback through established review platforms. Best garage door opener repair company designations often correlate with factory training completion, parts availability through authorized dealer networks, and demonstrated expertise with specific brands. Technicians specializing in particular manufacturers such as Overhead Door or Raynor possess detailed knowledge of model-specific components and programming procedures unavailable to generalist service providers.

Seasonal maintenance programs offered by professional services extend system longevity through systematic lubrication, adjustment service protocols, and component inspection identifying potential failures before complete breakdown occurs. Annual maintenance visits typically include comprehensive safety sensor test procedures, spring tension verification, roller replacement as needed, and track alignment assessment. These preventive interventions substantially reduce emergency repair requirements while maintaining optimal performance characteristics throughout the system’s operational lifespan.

What Are the Benefits of Same Day Repair Services?

Affordable garage door opener repair with expedited scheduling addresses security vulnerabilities and operational disruptions requiring immediate resolution. A garage door stuck in partially open position compromises property security and exposes interior spaces to weather elements, justifying premium service rates for rapid response. Same day repair providers maintain comprehensive parts inventories enabling immediate component replacement without delays for special ordering manufacturer-specific elements.

Emergency repair availability becomes particularly critical for commercial garage door applications where operational downtime directly impacts business revenue and logistics capabilities. Service agreements with guaranteed response times provide operational continuity assurance for commercial clients while distributing maintenance costs predictably across fiscal periods. Residential clients benefit from priority scheduling during extreme weather events or security-compromising failures requiring immediate professional intervention regardless of occurrence timing.

| Drive Type | Noise Level | Maintenance Needs | Common Repairs | Average Lifespan |

|---|---|---|---|---|

| Chain Drive | Moderate to High | Regular lubrication, tension adjustment | Chain replacement, sprocket wear, trolley issues | 10-15 years |

| Belt Drive | Low | Minimal, periodic inspection | Belt replacement, tension adjustment, pulley wear | 12-15 years |

| Screw Drive | Moderate | Moderate lubrication | Trolley carriage, rail assembly, drive screw wear | 10-12 years |

| Repair Type | Typical Cost Range | Time Required | DIY Feasibility |

|---|---|---|---|

| Remote Programming | $0-$75 | 15-30 minutes | High |

| Sensor Alignment | $75-$150 | 30-60 minutes | Moderate |

| Gear Replacement | $150-$250 | 1-2 hours | Low |

| Motor Replacement | $200-$350 | 2-3 hours | Very Low |

| Logic Board Replacement | $150-$300 | 1-2 hours | Low |

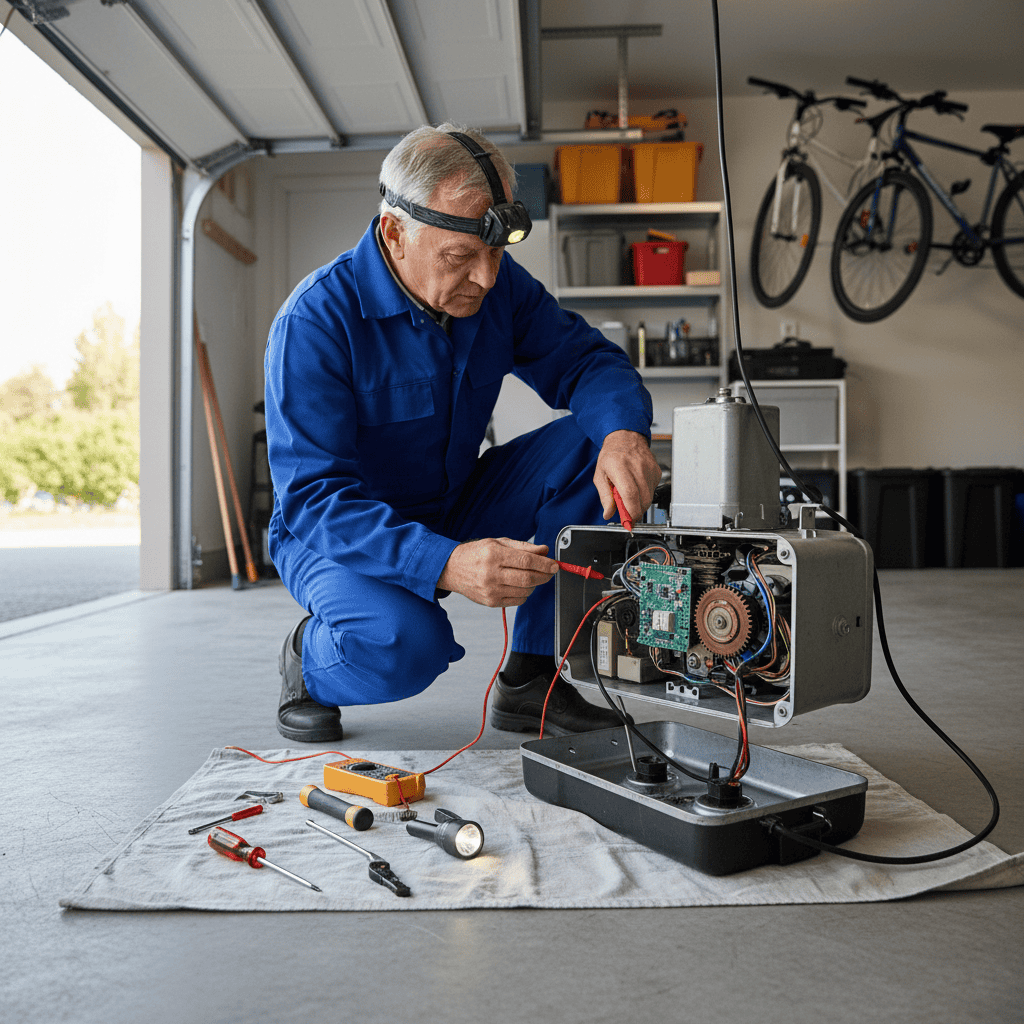

DIY Garage Door Opener Repair Versus Professional Service

DIY garage door opener repair approaches offer cost savings for mechanically inclined homeowners addressing straightforward issues such as remote battery replacement or basic limit switch adjustment. Owner’s manual documentation provides manufacturer guidance for user-serviceable procedures including emergency release operation, manual disconnect engagement, and simple troubleshooting protocols. However, complex repairs involving electrical components, spring systems, or precise calibration requirements typically exceed amateur capabilities and may void warranty coverage when performed without authorization.

Safety considerations fundamentally limit appropriate DIY repair scope, particularly regarding torsion spring and extension spring systems storing substantial mechanical energy. These components require specialized tools and training for safe manipulation, with improper handling creating severe injury risks. Professional repair service providers maintain liability insurance coverage protecting property owners from damages resulting from service errors, a protection absent when homeowners attempt repairs beyond their technical competency levels. The operator manual typically delineates which procedures remain within homeowner capabilities versus those requiring professional intervention.

Frequently Asked Questions

How do I know if my garage door opener needs repair or replacement?

Evaluate the opener’s age, frequency of malfunctions, and cumulative repair costs when deciding between repair and replacement. Units exceeding fifteen years typically warrant replacement due to outdated safety features and declining reliability. If repair costs approach fifty percent of replacement costs, or if the unit lacks contemporary safety sensors and auto-reverse mechanisms, replacement provides better long-term value and enhanced safety compliance with current standards.

Why does my garage door opener work intermittently?

Intermittent operation typically indicates electrical connection problems, including loose wiring terminals, degraded circuit board solder joints, or failing capacitor components. Temperature-sensitive issues suggest thermal expansion affecting connections or internal components reaching failure thresholds. Remote signal interference from nearby electronic devices or weakened transmitter batteries also produce inconsistent response patterns. Professional diagnostics can isolate the specific cause through systematic testing under various operating conditions.

Can I replace just the garage door opener motor without replacing the entire unit?

Motor replacement as an isolated repair depends on the opener design and parts availability from the manufacturer. Some units feature modular motor assemblies allowing independent replacement, while others integrate the motor with the gearbox and housing as a single assembly. For systems exceeding ten years of age, complete unit replacement often provides better value by incorporating improved technology, enhanced safety features, and warranty coverage compared to installing a replacement motor in an aging system with other components approaching failure.

What maintenance can prevent garage door opener repairs?

Preventive maintenance includes monthly safety sensor testing, visual inspection of moving components, and lubrication service for chain or screw drive mechanisms every six months. Annual professional maintenance should encompass comprehensive safety checks, force adjustment verification, travel limit confirmation, and hardware tightening. Keeping the photo eye sensors clean and properly aligned prevents closure problems, while monitoring unusual noises enables early detection of gear wear or bearing failures before complete breakdown occurs.

How long does professional garage door opener repair typically take?

Standard repair procedures such as sensor alignment, remote programming, or limit switch adjustment typically require thirty minutes to one hour for completion. Component replacement repairs including gear and sprocket replacement, capacitor installation, or receiver replacement generally take one to two hours depending on unit accessibility and design complexity. Extensive repairs involving motor replacement or complete logic board replacement may require two to three hours including diagnostic time, parts installation, and comprehensive operational testing to verify proper function.

What should I do if my garage door opener stops working suddenly?

Begin troubleshooting by verifying power supply at the circuit breaker and ensuring the unit receives electricity. Check whether the wall button functions when the remote control does not, isolating the problem to either the remote system or the main opener unit. Inspect safety sensors for alignment and obstruction issues causing closure prevention. If these